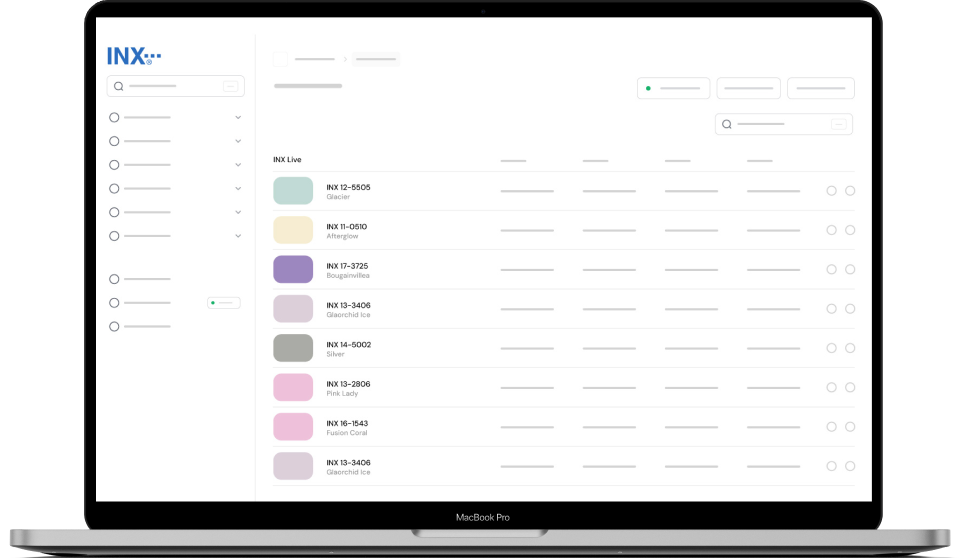

Process Control for Packaging Workflows

INX Color Quality ensures consistent, on-target color across jobs, inks, technologies, and sites, delivering reliable print quality worldwide.

Built for Packaging Quality Control

INX Color Quality App support the packaging industry by setting color targets and tracking key metrics like ink strength, opacity, and dot gain for improved process control.

Connected with Production Workflows

INX Color Quality Apps integrate with measurement systems, improving production efficiency.

Aligns Prepress and Pressroom

INX Color Quality Apps create a connected workflow using standard files for color targets and integrate with INX Ink Formulation for quick, efficient re-formulation when needed.

Specifications

INX Color Quality Apps – Color measurement and management solution for print and packaging.

ISO Standards

CxF 17972, PQX 20616, Security 27001

Color Differences Supported

∆E, ∆Ecmc, ∆E94, ∆E00, ∆Density, ∆Lab, ∆LCh

Supported Color Spaces

CIE Lab*, CIE LCh*(ab), CIE LCh*(uv), CIE XYZ

Configuration Options

Integraged with other Apps

Connectivity Options

USB, Bluetooth.

Spectros

X-Rite, CMA.

Minimum Display Resolution

1400 × 900 pixels or higher

Supported Illuminants

A, B, C, D50, D55, D65, D75, F2, F7, F11, UL35

Import / Export Formats

CxF, MIF, XTF, CGATS, ICC

INX Color Quality Capabilities

A True End-to-End Solution

INX Color Quality covers every aspect of color quality control across the packaging workflow, from specification to pre-media, ink room, and pressroom.

Comprehensive Analysis Capabilities

Monitor color quality in real time to detect issues early, reduce rework, and maximize jobs per press shift.

Compliance to Specifications

INX Color Quality delivers actionable feedback on color performance, ensuring every job meets customer specifications.

Get Expert Technical Support Anytime You Need

Our dedicated support team is here to ensure your INX Live experience runs smoothly— from setup to advanced troubleshooting.