💬

xxSOP - How to Measure on a Metallic Surface

Document Classification: Confidential

Reference: SOP-INX-01

Owner: Gerardo Cerros Version: 1.0

Approved by: Lisandro Robles Approval date: 10.21.2025

Areas covered by the procedure:

Purpose

This SOP outlines the procedure for using a spectrophotometer to measure the colors printed on metal cans for color control. The measurements will be taken on the flat sample and if possible, at three different angles (0°, 45°, and 90°) and averaged to ensure accuracy, OR the measurement can be taken directly on cylindrical can (straight wall or necked can) using a Tabletop, and if possible at three different points (top – mid – bottom).

Scope

This procedure applies to all personnel responsible for color quality control in the printing process on metal cans.

Equipment and Materials:

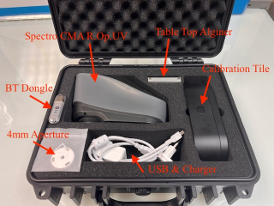

- Spherical Spectrophotometer + Tabletop for cans (Model: CMA R.Op.UV or X-rite Ci6x)

- Metal cans with printed colors

- Cleaning cloth (lint-free)

- Calibration tile (provided by the spectrophotometer manufacturer)

Procedure

Preparation

- Ensure the spectrophotometer is calibrated according to the manufacturer's instructions using the calibration tile.

- Clean the surface of the metal can with a lint-free cloth to remove any dust, fingerprints, or other contaminants.

Measurement Setup

- Turn on the spectrophotometer and allow it to warm up or to be at room temperature.

- Set the spectrophotometer to the appropriate measurement mode for metal surfaces.

- Illuminant D50 and Observer Angle at 2°

- SCI/SCE (Specular Component Included AND Specular Component Excluded)

- Define on the software or the Spectro the number of measurements to average

- Aperture 8mm or 4mm, depending on the measurement surface.

Taking Measurements

- Position the spectrophotometer at a 90° angle relative to (“stamping direction”) the surface of the metal can.

- Ensure the measurement aperture is in full contact with the can surface to avoid any light leakage.

- Automatic Record the measurement made by the software.

- If required: Repeat the measurement at a 45° and 90° angle.

- Rotate the spectrophotometer or the can as necessary to achieve the measurement angle.

- Ensure the measurement aperture is in full contact with the can surface.

- Use the spectrophotometer's software to compute the average

- Automatic Record the measurement made by the software.

Cleaning and Maintenance

- After completing the measurements, clean the spectrophotometer’s measurement aperture with a lint-free cloth.

- Store the spectrophotometer in a its original case, dry place as per the manufacturer’s recommendations.

Safety and Quality Control

- Always handle the spectrophotometer and metal cans with care to prevent damage.

- Ensure the work area is clean and free from contaminants that may affect the accuracy of the measurements.

- Regularly check the calibration of the spectrophotometer to maintain measurement accuracy.

Troubleshooting

- If the spectrophotometer gives inconsistent readings, recalibrate the device and repeat the measurements.

- If the measurements are still inconsistent, inspect the spectrophotometer and the metal can for any damage or contamination.

- Control Spectro last revision date as per manufacturer requirements.

Images